In-house Tooling & 5-Axis CNC Trimming

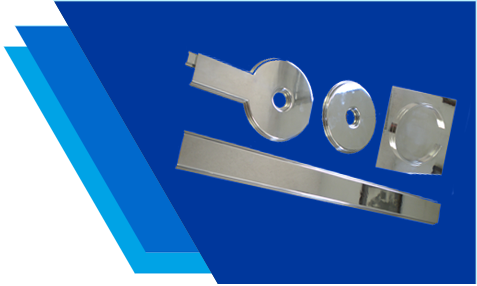

Whether your project requires aluminum molds with precision dimensional stability, composite molds for medium or low volume runs or wooden/plaster molds for short run prototype parts, Lormac’s expert engineering assistance will provide cost effective options in a timely manner. Our experienced team is proficient on SurfCam and SolidWorks and are capable of turning concept to design and quickly producing quality prototype and production tooling for vacuum and pressure forming.

CAD/CAM file types accepted: SolidWorks (.prt, .sldprt), IGES, Step (.stp, .step), Surfcam tool files (.scctl)

Lormac’s Tooling & 5 axis CNC Capabilities include:

- 4x 5-axis CNC machining stations up to 60×120”

- 1x 3-axis CNC Machining station up to 36×48”

- Expert design assistance

- Tool Fabrication

- Prototyping – quick turnaround on modifications

- Routing/trimming with a high degree of accuracy

- Plastic fabrication

Lormac Related Articles: